Recently, a large construction company became the first to use 3D printing technology on a commercial project. The Chinese company WinSun used a 20-foot tall printer to lay down a prototype of a six-story apartment building, with walls and plumbing included. Although the quality was not high enough for most large-scale projects, the company proved that 3D printing would revolutionize construction. Civil engineer Reddy Kancharla talks about how this technology will impact construction and design for major projects.

What are the benefits of 3D printing over traditional construction techniques?

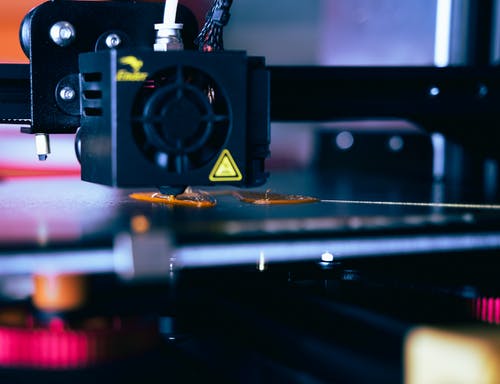

3D printing technology can construct complex shapes that would otherwise be very difficult and expensive using traditional construction techniques. This technology also uses less material, reduces waste, and requires little to no construction crew. In addition, this process is more environmentally friendly because it saves trees from being chopped down for timber, reduces energy consumption, and eliminates the need for construction equipment.

For example, 3D printing is very useful when the size of a building is too large to be constructed using traditional methods, or there are curves involved in the design of a structure. For this project by WinSun, they constructed an entire six-story apartment building and took advantage of curves and angles that would normally not be possible with traditional construction. However, if there were windows, doors, or other areas where the structure is opened up to the elements, this process might not work as well because of its reduced strength.

Will 3D printing revolutionize the architecture field?

3D printing could indeed revolutionize the architecture field. 3D printers can print much larger structures than we can build with traditional construction methods because the materials and workers would be much more expensive and difficult to transport. 3D printed structures would also be lighter and cheaper, making them a better option for remote areas where it is simply impossible to transport materials. With the price of 3D printers falling, this technology will likely become more accessible to all areas and types of construction projects.

What are some potential drawbacks to using 3D printing for construction?

3D printed structures need to be able to counteract not only vertical forces but horizontal ones as well. Our environment plays a significant role in the forces that structures are subjected to, particularly tall buildings. The wind is one of the most destructive forces that a building must withstand. If strong enough winds can get into the structure, even small cracks or permanent deformations can cause the entire building to collapse. The ability of 3D printed structures to resist these forces has not been fully tested yet, so this could be a major drawback for using this process on large-scale projects.

How do you see 3D printing changing construction in the future?

3D printing is highly likely to change how we build things in the future. Although more expensive right now than traditional construction methods, it is not out of the realm of possibility that 3D printers could be used for all major construction projects. Together with the technology of robotics, future buildings may even be able to create their structural elements as needed or perform repairs independently if necessary. In terms of large-scale projects, this could revolutionize how we think about building by significantly reducing waste and energy consumption from construction vehicles and equipment.